Falcon XP

Updates

Page 2

The first page was

getting too big and the pictures weren't all loading the first time, so I've

decided to split the pages up to keep load time for dial up users (like myself)

down to a minimum.

31 Jan 04

The move. We had

moved the Falcon's fuselage to Air park back on Thursday, but didn't bring the

camera. Then, on Saturday, Dad, Hal Lorenz, Coy, Dale Lorenz and myself

loaded the wings, ailerons, trailing edges and other bits onto my race trailer

and moved it all out to Air park. There, we attached the wings, ailerons

and trailing edges. We saw the full painted airplane together for the

first time ever. Next will be gauges, engine and canopy.

L-R: The wings and bits loaded on my race trailer. The fuselage waiting

for it's wings. Right after we got the wings on.

L-R: Other side (port?) after wings were on. Looking at the top where the

two painted wings come together. 12 foot fuselage with a 38 foot wingspan

pictured with (l-r) Hal Lorenz, Alyssa Lorenz, Dale Lorenz.

05 and 07 Feb 04

Dad and I went out to

airpark and attached the canard and winglets. It's was a pretty cold day

and with the wind gusting to 20 mph, it made it a little too cold for these two

Southern Boys. We did the bare minimum for today and bugged out.

Three pictures of the canard after we attached it.

L-R: Me holding the right winglet while Dad inserts the bolts. Dad and I

tightening the winglet. Me in the fuselage trying to fish out a rudder

control cable that got pushed up into the wing. I didn't get it out this

day, but I'll get it next time.

Feb-Mar

04

We have been working on

the Falcon, but it's stuff that isn't very "picture-worthy. We've been wiring

out from the instrument panel to the engine, mounted the throttle cables and

choke cables. A lot of tedious and time consuming work. We've

mounted and dismounted the engine about 15 times now. We are making small

steps, but we aren't there yet. We've had business trips, air shows and

family commitments that have slowed progress. Keep the faith, we're getting

there.

L-R: Me cutting the choke cable. Dad hooking up the cables in the

fuselage.

18 Apr 04

It's coming along.

We have been able to mount the new two-piece canopy on the Falcon. We put

about 10 hours of work into the canopy on this day.

L-R: Me attaching the brace. Dad marking the lexan. Me cutting the lexan.

L-R: Dad and I Fitting, taping and trimming. Dad taping before we start

drilling. Dad inserting cleco's before we rivet.

19 Apr 04

Dad was off work this

day, so he worked all morning and then I dropped by that afternoon to help out.

He had the canopy all but finished by the time I got there.

L-R: Dad riveting the canopy. Dad riveting the back portion. The

left side view.

L-R: Dad working on the right side. The 90% finished product. The closed

canopy.

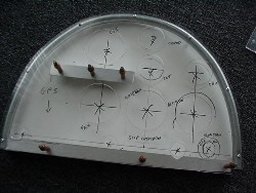

L-R: Dad measuring the inside. We are going to move the instrument aft about 6

inches, so we needed the template to make the new one. The new position

strobe. We also two more that will go on each wing tip.

25 Apr 04

Dad was off this

day to start on relocating the Instrument Panel. We decided to move it aft

about 6 inches to make the instruments closer to read and get the switches

within better reach. The 6 inch gap between the old panel and the new one

will be nice in helping with the wiring of the instruments and switches.

L-R: The tools used to make the template. Dad bending the tubing to match

the shape of the canopy. The cardboard template with intercom, GPS and

compass attached.

27 Apr 04

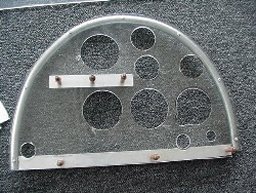

The first panel was made

from Acrylic. Dad found out real quick, acrylic doesn't like to be cut.

It shattered while cutting out the last hole. So, he started over and made

the next one from Lexan. He figured, if it's strong enough to be the

canopy, it can surely hold some instruments.

L-R: The new panel. The new panel with the template behind it.

29 Apr 04

We test fitted the new

panel today. You ask why there were two days between the making and test

fitting? Air Park, where the Falcon is located clear across town from where dad

lives.. It's about a 30-40 minute trip there and it's a trip he doesn't make

everyday. He's hoping to, one day, have a house near the hanger or a

hanger near the house.

L-R: Making the template for the original panel cover. The new panel test fit.

Closer shot of the new panel test fit.

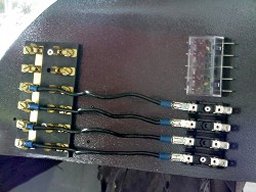

03 May 04

Set the newly painted

panel in temporarily. (It needs to be able to come out so we can finish the

wiring. We also mounted the 2 fuse busses on the old panel cover. We also

pulled the engine off (again), took it home and started putting the gear

reduction "E-box" together to mount on the engine. I was humming along

putting it together, but the directions weren't written for a complete novice

like myself, so I had to put it away for a day, call Ronnie at South Mississippi Rotax and get some very helpful advice.

L-R: New panel installed. New panel with fuse bus visible. Fuse busses

installed.

L-R: Taking off the belt drive. The bare Rotax 503. Me torquing the

attaching bolts of the e-drive.

10 May 04

Dad was off

again.. (He's off each Monday) He was able to attach the velcro for the wing gap

cover. The wings have a 2 inch gap between them and a piece of fabric is

used to cover it. The fabric is just velcro'ed in place. He also

pulled the protective covering off the lexan and mounted the engine one more

time. The engine will come off once more when the proper bolts that are

used to mount it come in the mail.

L-R: The fabric covering the gap. The blue tape is keeping everything in place

while the glue on the velcro dries. Dad in the Falcon attaching the side

straps. Head on shot of the Falcon. It's really not as cramped as it

looks.

L-R: The canopy and new seats installed. The new propeller. The Rotax 503

with the E-drive installed.

14 May 04

We have started to

install the instrument panel.

L-R: The new power distribution panel with fuse busses. Close up of

panel and busses. New instrument panel. The to empty spaces will

house the VSI (vertical speed indicator) and compass.

17-18 May 04

Still working on

the instrument panel. Dad was able to mount the panel a couple of days ago

and now we are wiring everything up. He came and mounted the common ground

yesterday. Today we started to wire the EGT and

CHT gauges. We had to splice a jumper wire to make the connection long

enough and then run the wires through the fuselage. The CHT

thermo-couplers ended up being the wrong size so we couldn't finish up today.

We started losing daylight before I had a chance the splice the EGT wires.

I'll get to them on Thursday.

L-R: Dad wiring up the ignition switch. Me soldering the jumper wire for

the CHT. Me tightening the bottom cover of the engine.

The EGT temp probes.

20 May 04

More wiring..

Wired up the EGT's, the CHT's and more of the panel.

L-R: Dad soldering more connections. Dad soldering. Behind the panel after

more wires added.

22 and 24 May 04

After the EAA

Picnic on 22 May, Dad and went about wiring more things in the Falcon. The

biggest hurdle crossed this day was getting the strobes wired up and grounded so

they all work. On 24 May, Dad mounted the working strobes.

Mounted strobe.

27 May 04

Dad and I worked on

mounting and connecting the carburetors, choke and throttle cables. He

already had the muffler mounted by the time I got there. As for the rest,

well, actually, Dad worked on 99% of it. I had attend a work Picnic and then

showed up just to kind of help out for a couple hours. I didn't do much

this day.

L-R: The mounted muffler. Dad working on the throttle cable for the carb.

Dad working on the throttle cables from a different angle. :)

Carbs, cables, and muffler all mounted.

29 May 04

Dad mounted the fuel pump

and ran the fuel lines today. I was preparing to paint my house, so he had

no help today.

L-R: The mounted fuel pump can be seen about 2 o'clock from the rear air filter.

Inside the fuselage pod looking at the fuel primer bulb.

10 Jun 04

Everyone has been so busy

with other duties, we haven't been able to spend much time on the Falcon lately.

Dad did go out there today and mount the front seat permanently, attached the

rear seat rudder pedals onto the back of front seat and attached and lubricated

the cables. He also remounted the fuel pump with dampeners to fight

vibration. And, he put the new velcro on the seats to hold the

cushions and repalced the flutter bar bolts with the proper length bolts. (The

old ones were too short) No pics this time.

22 Jul 04

Dad has made a few

trips out and worked a couple things. Our schedules have finally allowed us to

start working together

again this week. We went about attaching the engine primer bulb today. We

had to fabricate the lines and then we were going to mount it. Mounting needs a

"shelf" fabricated. Dad will make that and we'll mount it Saturday. We

also ran across a problem with the throttle and choke cables not moving now

that everything is hooked up. We'll try and find someone to help us

troubleshoot that.

L-R: The T-junction for the fuel tank. Dad putting together the engine

primer hoses.

24 Jul 04

After our EAA

meeting, Dad and I went back out to Air Park to work on the Falcon. On the

way, we stopped by Elrod's Field and got some helpful advice from Bob Edmonton

and the Ultralight guys. We were able to finish up the engine wiring,

mount the new instruments, wash it and apply the logo decals.. We worked

for about 8 hours in 101 degree temps. But, considering what we were able

to accomplish, it was worth it.

L-R: The XP after Dad washed it. Looking head on.. 38 feet of wing comin' at ya!!

Me with the Falcon.

L-R: Me applying the XP decal. The decal on the plane. A close up of

the decal.

28 Nov 04

Dad sold the Falcon.

The guy that bought the Falcon will be doing a website as well, so we will link

to his to keep up with the progress. He promised Dad when he was done, both he

and I will get an hour each in the airplane. Sounds cool to me.

January

2008

The Falcon is flying!!! The

guy that bought it sent us a video a week ago showing the Falcon make it's first

flight since we bought it. It looked great to see that thing take to the

air. We're talking about making a trip to Tennessee to see it for ourselves (and

maybe bum a quick ride in it)